APPLICATION

APPLICATION

- Ideal for drying adhesives, ink, paint & epoxy bonding/curing.

- Laminating.

- Shrink Packaging.

- Thermoforming Plastics.

- Other process requiring fast penetration of heat into metals, wood, synthetic fabrics & plastics.

CONSTRUCTION

CONSTRUCTION

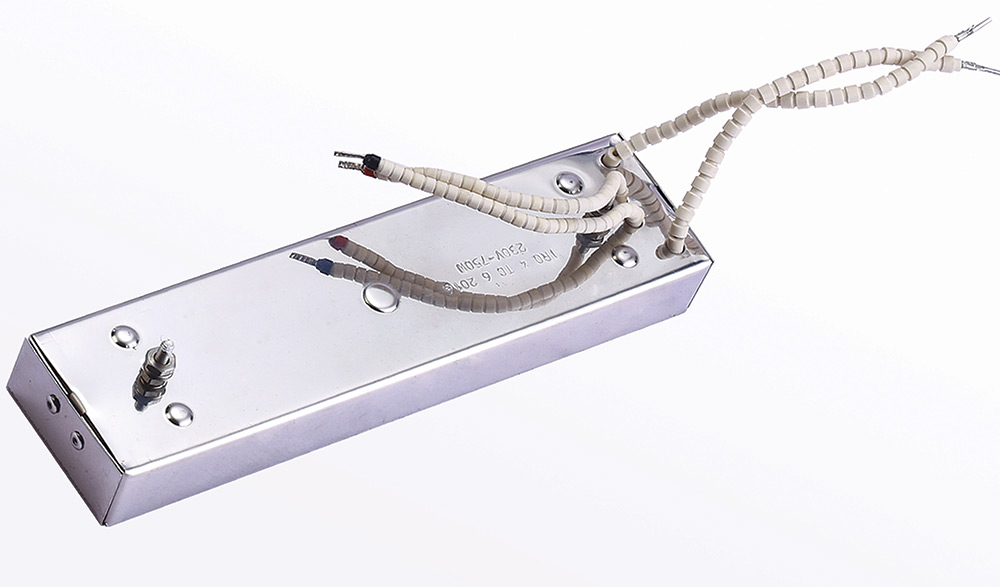

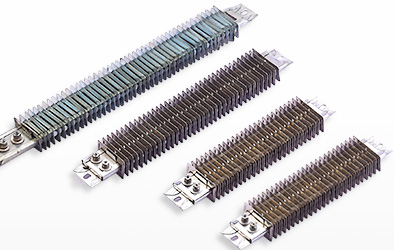

Quartz emitters provide medium wavelength radiation and can be the most preferred source of heat when rapid heater response is needed. The modules are comprised of a series of quartz tubes running parallel to each other within a highly reflective steel housing. Each tube contains a coiled resistance wire available in a variety of wattages and voltages. The large variety of sizes, shapes, and watt densities allows quartz emitters to be highly useful in zoning arrangements such as plastic thermoforming sheet-fed applications where complex heating patterns are needed, high-speed roll-fed processes, and machines requiring precise zone control because they are small in size, and can easily be put in larger panels.

FEATURES

FEATURES

- Standard Industry Sizes & Rating up to 40W /sq. Inch.

- For fast heating & better reflection it is also available in Quartz Clear tubes / gold coated tubes etc.

- Highly reflective rugged Steel housing construction.

- Standard winding pattern gives uniform heating over entire face of heater.

- Optional built-in type K or J T/C available.

- Ideal for systems requiring small area zooming & close control of process.

- Best when used at radiation distances of 4-10” from work.

- Suitable for horizontal or vertical operation with tubes in horizontal plane.

- Can be design in different Voltages.

- More responsive heat-up & cool-down.

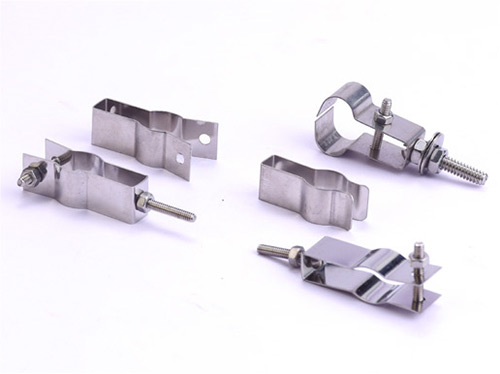

Mounting Clips

INSTALLATION & PRECAUTIONS

INSTALLATION & PRECAUTIONS

- White Cotton gloves should be worn when handling Quartz Elements. Never touch elements with bare hands.

- Oils & contaminants from the skin could be deposited upon the Quartz Sheath & would cause hot spots & possibly pre mature failures.

- As a safety necessity use approved conductors and connectors as per the National Wiring Laws so that the wires and connectors used for connections do not get heated up.

- For isolation and protection against short circuits of Heaters appropriate approved Double pole breakers to be used as per the total current of the group of heaters used.

- Any Metal part of the heaters shall always be earthed. To avoid short-circuits, the leads must not come into contact with sharp edges and/or objects.

- Always use appropriate controller for the better life of heater.

- The symbols for warnings and Cautions for the High Voltage and the High Temperature shall be placed near the part of end use.

- Any forced cooling, circulating requirement of the process shall also be taken care of, May be a wiring diagram with such requirements with heaters shall be placed near the target area.

- During changing / checking of heaters ensure that the incoming Mains Voltage are disconnected.

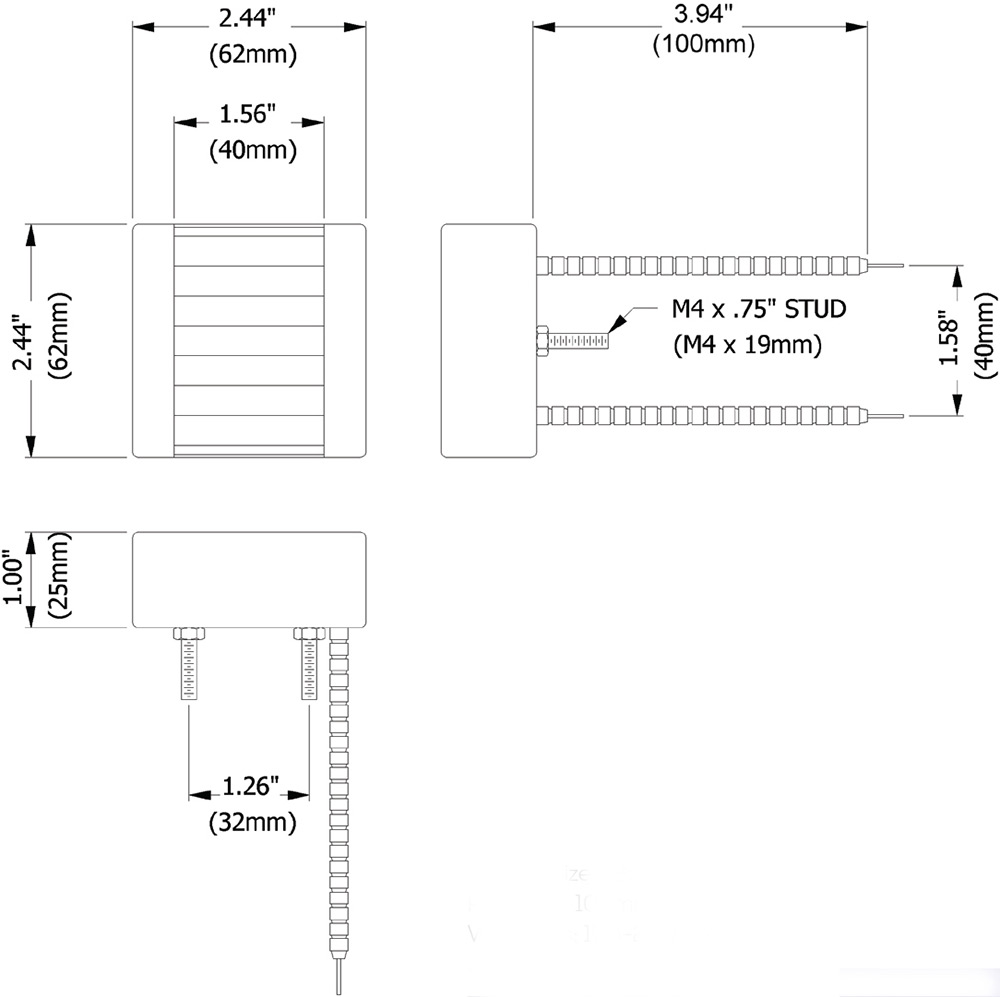

STANDARD SIZES

STANDARD SIZES

Overall Size: 62mm x 62mm Radiaton: 62mm x 40mm Wattages: 75-150-200 W

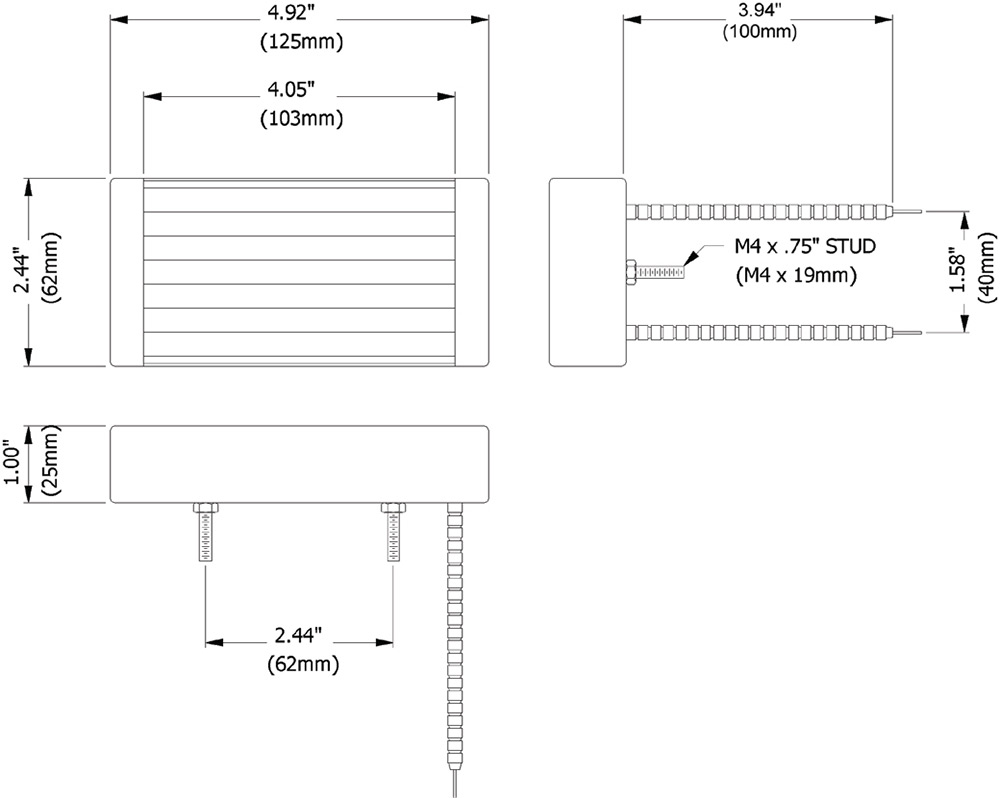

Overall Size: 125mm x 62mm Radiaton: 103mm x 62mm Wattages: 150-200-325-500 W

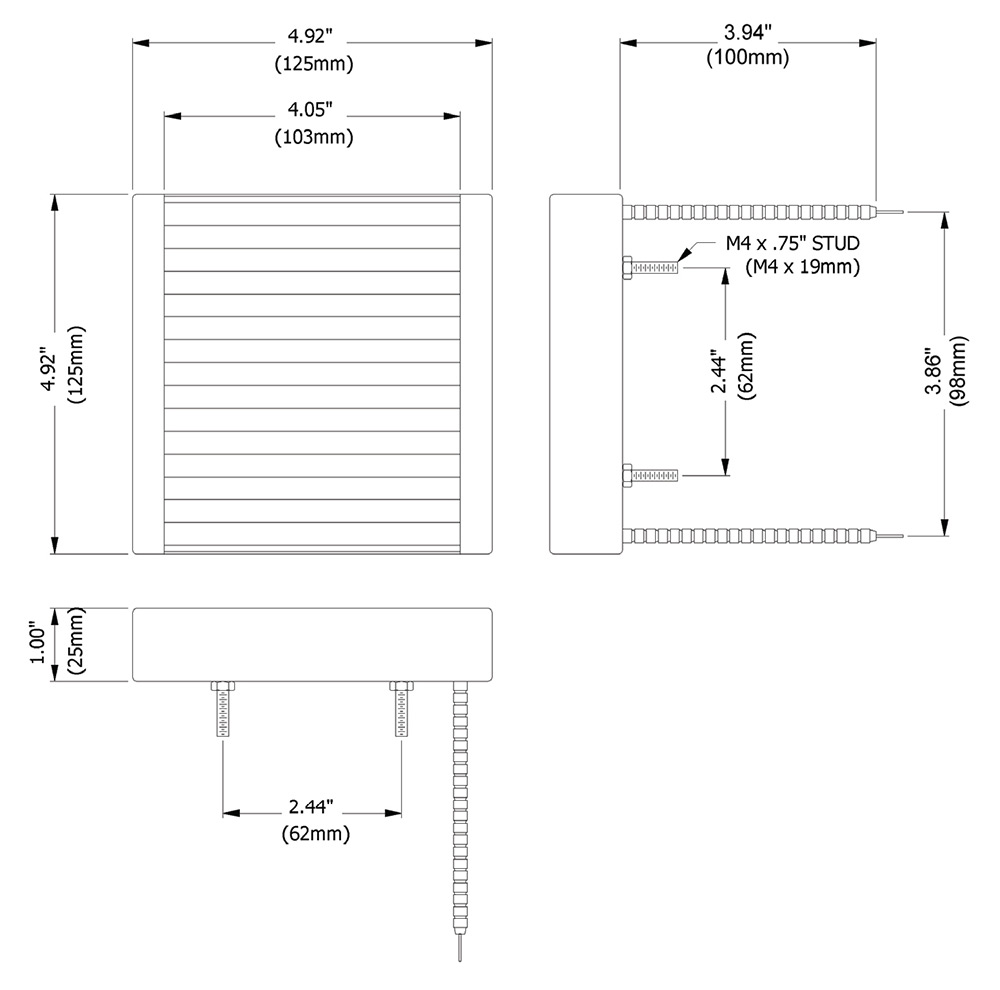

Overall Size: 125mm x 125mm Radiaton: 125mm x 103mm Wattages: 300-400-500-750 W

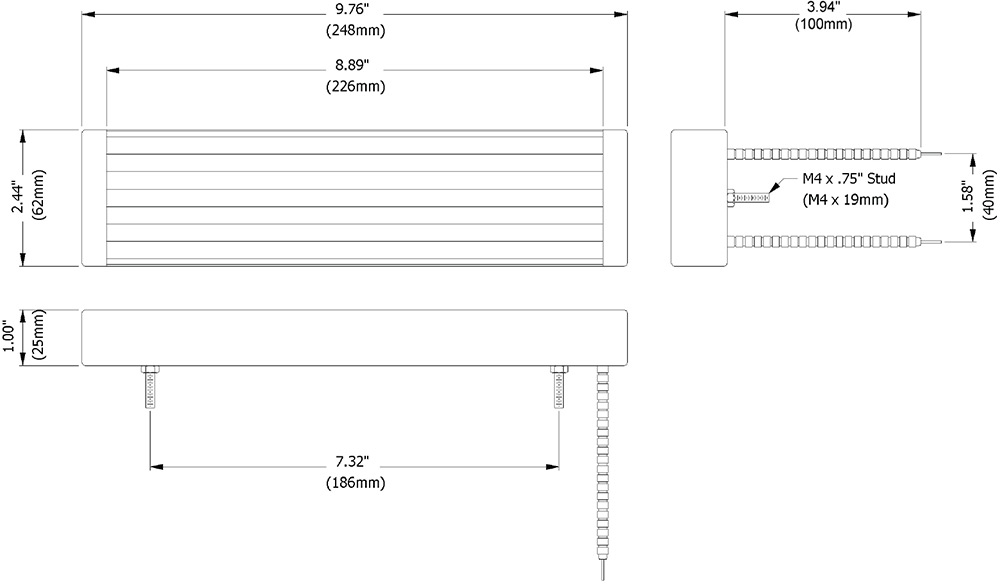

Overall Size: 248mm x 62mm Radiaton: 226mm x 62mm Wattages: 300-400-500-750-1000 W

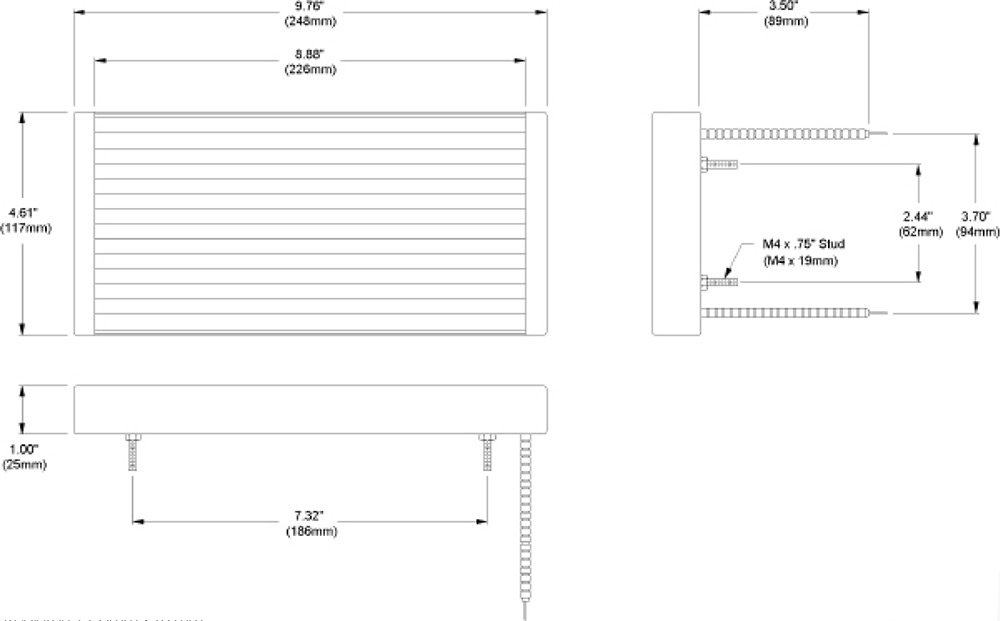

Overall Size: 248mm x 117mm Radiaton: 226mm x 117mm Wattages: 750-1000-1250 W

AVAILABLE with BUILT-IN THERMOC OUPLE

in all sizes (Type J or K)