APPLICATION

APPLICATION

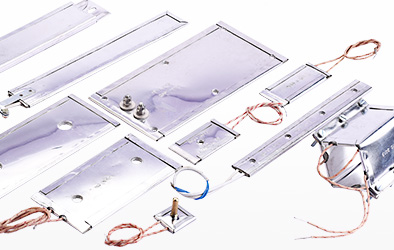

Heaters are used in various applications, due to their being intrinsically reliable and highly versatile. They were first designed for a very specific application, the differential heating of plastic injection nozzles, and later become invaluable in the most diverse and demanding applications. Aerospace, railway, chemical, metalworking and food industry, glass and paper indus-try, automotive, packing, medical industry... all have taken advantage from the use of heaters, with their wide range of possible shapes and their fitness to an unlimited number of applications.

CONSTRUCTION

CONSTRUCTION

Microtubular coiled heaters are manufactured to a revolutionary design, which makes them the best choice in the most demanding conditions. The resistive wire is uniformly distributed in a compacted MgO insulation, with a CrNi-steel outer protection sheath. The heaters are annealed after manufacturing, thus acquiring a high malleability that allows their being subsequently bent into any complex shape, with extremely narrow bending radius.

FEATURES

FEATURES

- A very wide contact surface results in exceptionally high levels of thermal conductivity towards the body that needs to be heated.

- Optimal insulation results in very long life duration

- Heavy-duty construction results in very high resistance to mechanical shocks

- Operation temperature up to 700°C (1300°F)

- Very low mass results in extremely low thermic inertia

- Optional built-in thermocouple for high-resolution temperature measuring (J-type standard; K-type on request)

- Unlimited range of possible shapes obtained from the straight heater

- Heaters can be incorporated into brass or aluminium castings

- Available in cross section 2.4mm x 4.2mm & 3.3mm x 3.3mm.

MICRO TUBULAR COIL HEATER S

| Length (mm) +3% |

Heated Length (mm) +5% |

Power (W) with 230V +10% |

Power Density (W/cm) with 230V |

| 300 | 205 | 175 | 5.4 |

| 350 | 255 | 210 | 5.4 |

| 400 | 305 | 250 | 5.4 |

| 450 | 355 | 280 | 5.4 |

| 500 | 405 | 315 | 5.4 |

| 550 | 455 | 350 | 5.4 |

| 600 | 505 | 385 | 5.4 |

| 700 | 555 | 450 | 5.4 |

| 800 | 655 | 525 | 5.4 |

| 900 | 855 | 600 | 5.4 |

| 1000 | 955 | 600 | 5.4 |

| 1200 | 1155 | 800 | 5.4 |

Also available in square section 3.3 mm x 3.3 mm